Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

DJ type Wave shaped edge high dip angle belt conveyor

Classification:

DJ type high dip angle belt conveyor is continuous conveying equipment for general purpose on bulk materials, using a conveyor belt with wavy baffle (Skirt edge conveyor belt, skirt edge separator conveyor belt). Therefore, it is especially suitable for high dip angle transportation.

Contact:

PRODUCTS

Details Introduction

Overview

DJ type high dip angle belt conveyor is continuous conveying equipment for general purpose on bulk materials, using a conveyor belt with wavy baffle (Skirt edge conveyor belt, skirt edge separator conveyor belt). Therefore, it is especially suitable for high dip angle transportation.

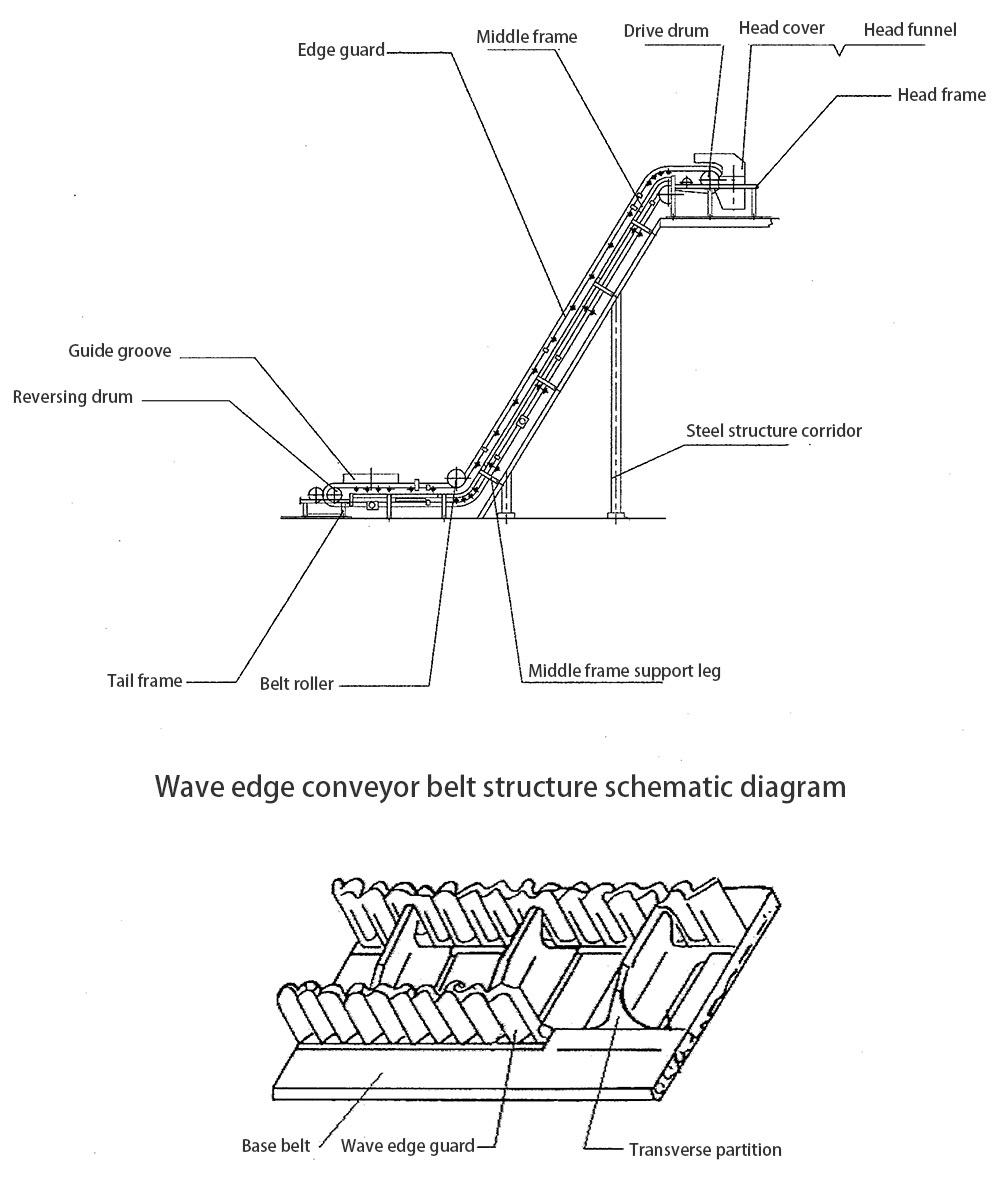

Major component

Head and tail wheel, frame, all kinds of rollers, rollers, tape, tension device, counterweight block, safety device, driving device, control device, etc.

The conveyor belt with large Angle wavy rib is composed of three parts: baseband, rib and transverse partition. The retaining edge is used to prevent the material slipping and scattering. In order to facilitate the bypass of the drum, the edge is designed to ripple; The role of the transverse diaphragm is to support the material, in order to achieve large Angle transportation, the use of T-type TC type. The baffle and the baffle are connected to the baseband by the method of secondary vulcanization, and have a high connection strength.

Structural form

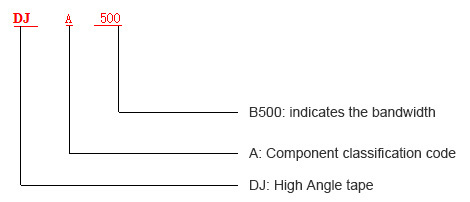

Model description

Application working condition

It is suitable for continuous conveying of materials with large inclination Angle (up to 90°). The bulk density of the conveying material is 0.5 ~ 2.5t/m3, and the working ambient temperature is within the range of -25℃ ~ +40℃. For conveying high temperature, acid and alkali, oil or organic solvents and other components of the material, need to use a special flange conveyor belt.

Application industry

It can be used in coal, chemical industry, building materials, metallurgy, electric power, light industry, grain, port, ship, thermal power and other industries.

Main innovations:

● Large throughput, vertical lifting height up to 200m.

● Save equipment floor space. When conveying materials vertically, the maximum size of the material can reach 200mm.

● Completely solve the transmission Angle that cannot be reached by the ordinary pattern belt conveyor. Smooth transition from horizontal to inclined (or vertical);

● Low energy consumption, simple structure, easy maintenance.

● High strength tape, long service life.

● Low overall investment cost, can save 20%-30% of the investment cost

● Suitable for conveying easily scattered powder, granular, small block, paste and liquid materials;

Main technical parameters

|

Bandwidth(mm) |

300 |

400 |

500 |

650 |

800 |

1000 |

|||||||||

|

Rib height H(mm) |

40 |

60 |

80 |

80 |

120 |

80 |

120 |

160 |

120 |

160 |

200 |

160 |

200 |

240 |

|

|

Throughput (raw coal, belt velocity 1m/s)m3/h |

30° |

16 |

28 |

36 |

50 |

70 |

74 |

105 |

122 |

135 |

164 |

204 |

240 |

300 |

359 |

|

45° |

12 |

19 |

25 |

33 |

60 |

49 |

90 |

106 |

116 |

142 |

175 |

195 |

240 |

310 |

|

|

60° |

9 |

15 |

19 |

23 |

41 |

35 |

61 |

75 |

78 |

100 |

120 |

137 |

165 |

210 |

|

|

90° |

5 |

9 |

11 |

15 |

24 |

23 |

36 |

45 |

46 |

60 |

85 |

82 |

120 |

145 |

|

Note: 1 . the conveyor capacity is calculated according to the belt velocity V=1.0m/s

2 . the throughput is calculated according to the horizontal area (that is, the material dynamic accumulation Angle P=0)

Keyword:

DJ type Wave shaped edge high dip angle belt conveyor

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China