Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

High Clean Air Bag Dust Collector (patented technology)

Classification:

GCDM series High Clean Air Bag Dust Collector is a practical and efficient product with independent intellectual property rights developed by our company on the basis of summarizing the practical experience of ESP and long bag low pressure pulse bag dust collector widely used in metallurgy, electric power, building materials and solid waste industries over the years, and drawing on the experience of advanced boiler dust removal technologies from abroad. It can better adapt to the combustion characteristics and flue gas characteristics of domestic boilers and industrial boilers; The bad conditions that may occur in the running process of the boiler are fully considered, such as combustion-supporting with oil, abnormal smoke temperature, "four pipe" burst etc.

Contact:

PRODUCTS

Details Introduction

Overview

GCDM series High Clean Air Bag Dust Collector is a practical and efficient product with independent intellectual property rights developed by our company on the basis of summarizing the practical experience of ESP and long bag low pressure pulse bag dust collector widely used in metallurgy, electric power, building materials and solid waste industries over the years, and drawing on the experience of advanced boiler dust removal technologies from abroad. It can better adapt to the combustion characteristics and flue gas characteristics of domestic boilers and industrial boilers; The bad conditions that may occur in the running process of the boiler are fully considered, such as combustion-supporting with oil, abnormal smoke temperature, "four pipe" burst etc.

Working mechanism:

The dusty gas passes through the inlet horn of the dust collector, and the inlet horn is provided with a grading air distribution plate inside. Some large particles of dust fall directly into the hopper after separation through the air distribution plate, and the rest dust enters the filter area of the middle case with the air flow under the guidance of the diversion system, and is adsorbed on the outside surface of the filter bag. The filtered clean gas is discharged through the filter bag through the upper box and through the exhaust duct.

The working principle of the ash cleaning system: the compressed air transmits the filtered air through the gas pipeline to the storage tank of each pulse valve. Then the compressed air is sprayed into the filter bag instantaneously through the nozzle at the lower part of the fixed spray pipe to achieve the purpose of ash cleaning.

Main component

It is composed of high clean air chamber, middle case, hopper, air distribution system, air inlet and outlet flue, pulse cleaning system, heating system, anti-blocking system, insulation system, electrical control system etc.

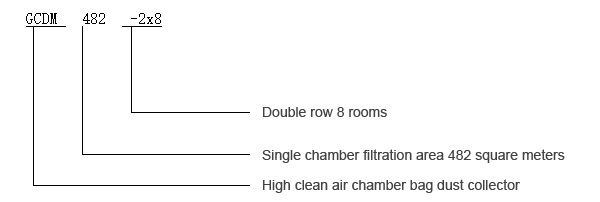

Model description

Range of Gas flow processing

30000~3000000m3/h, the outlet emission concentration is lower than 50-5-5mg/Nm3.

Applicable industry

Metallurgy, building materials, electricity, light industry, chemical industry, solid waste and other industries.

Main innovations:

● high Clean Air chamber technology

● Diversion technology

● Air leakage rate of purification chamber 0.5%

● Combined air distribution, less equipment footprint

● Fixed pipe blowing technology

● Bypass valve zero leakage technology

● Double section filter cage structure and easy maintenance

● Technical measures to ensure long life of filter bag

● Prevention and measures are provided for low-temperature danger of flue gas

● Automatic detection and protection

● Protective measures of dust collector when tube burst occurs in boiler operation

● Protective measures when the inlet smoke temperature exceeds the permissible temperature of the filter bag

● Protective measures for full oil injection and low load combustion-supporting with oil when the boiler starts

● Technical measures to prevent oxidation corrosion of filter bags

● Technical measures to prevent acid corrosion of filter material

● Dust hopper anti-blocking measures and necessary maintenance measures for dust hopper equipment

● According to the characteristics of different smoke , different working conditions and requirements, we can ensure that the emission index reaches or less than 5 ~ 20mg/Nm3 through a series of technical measures.

Independent intellectual property

1, patented technology - dust collector internal bypass design technology

2, patented technology -- bypass valve gas seal technology (low pressure gas chamber seal device)

3, patented technology - bypass valve open control automatic regulation technology

4, patented technology - Process Safety One-click Protection Technology

5. Patented technology -- fireproof device

6, patented technology - zero leakage lifting valve

7, patented technology - special bag dust collector

GCDM long bag pulse series bag dust collector technical parameters

|

Model number |

Gas flow (m3/h) |

Total filtration area(m2) |

Number of dust removal chambers(pcs) |

Total number of filter bags (pcs) |

Filter bag size(mm×mm) |

Filter wind velocity(m/min) |

Dust removal port resistance(Pa) |

Inlet gas dust concentration(g/Nm3) |

Outlet gas dust concentration(mg/Nm3) |

efficiency(%) |

Injection pressure(MPa) |

|

GCDM-482/4 |

128614 |

1929 |

4 |

640 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/5 |

160768 |

2412 |

5 |

800 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/6 |

192922 |

2894 |

6 |

960 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/7 |

225075 |

3376 |

7 |

1120 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/8 |

257229 |

3858 |

8 |

1280 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/9 |

289382 |

4341 |

9 |

1440 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/10 |

321536 |

4823 |

10 |

1600 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/2x4 |

257229 |

3858 |

8 |

1280 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/2x6 |

385843 |

5788 |

12 |

1920 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/2x8 |

514458 |

7717 |

16 |

2560 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

GCDM-482/2x10 |

643072 |

9646 |

20 |

3200 |

160×6000 |

0.9 |

<1200 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

Keyword:

High Clean Air Bag Dust Collector (patented technology)

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China