Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

LCDM series long bag pulse dust collector

Classification:

The long bag low-pressure pulse dust collector produced by our company is an external filter long bag dust collector that can be offline maintained (dust cleaning) in separate rooms

Contact:

PRODUCTS

Details Introduction

Overview

The long bag low-pressure pulse dust collector produced by our company is an external filter long bag dust collector that can be offline maintained (dust cleaning) in separate rooms . It have long bag offline pulse dust removal technology and product with international advanced level, which combines years of research results and technical experience, and integrates the best international long bag offline pulse dust removal technology. It is a large-scale dust removal equipment with high air volume, good dust cleaning effect, high dust removal efficiency, reliable operation, easy maintenance, and small footprint. Its main features are: using large DC pulse to reduce the pressure of compressed gas for pulse cleaning, saving energy; Each nozzle on the spray pipe is aligned with the center of the bag and sprayed into each filter bag. Due to the large amount of airflow induced by the accelerated movement of gas, the dust cleaning effect of the spray is greatly improved, and the bag length can reach 6-8 meters, reducing the footprint. The equipment adopts PLC control for pulse blowing and ash removal, and users can choose timing or constant pressure difference method according to their needs.

Working mechanism

When the LCDM series long bag pulse dust collector is in operation, the dusty gas enters the hopper through the inlet duct, and the coarse dust particles directly fall into the bottom of the hopper. The fine dust particles enter the middle case with the airflow, and the dust accumulates on the outer surface of the filter bag. The filtered gas enters the upper case, the outlet duct, and the outlet stack through the bag mouth inside the filter bag. The dust collector combines the advantages of spraying and pulse cleaning, with strong cleaning ability, high dust removal efficiency, low emission concentration, low energy consumption, and low air leakage rate. Adopting measures such as microcomputer control, chamber spraying, timed dust cleaning, and automatic protection against ultra-high temperatures.

The cleaning process involves first cutting off the clean air outlet duct of the room, so that the bag in the room is in a state of no airflow passing through (stopping the air flow for cleaning in the room), and then opening the pulse valve to use compressed air for pulse cleaning. Fully automatic control can be achieved through programmable software on exhaust valves (lift valves), pulse valves, ash discharge valves, cold air valves, safety valves etc.

Main component

The dust collector is composed of upper case, middle case, ash hopper and support, spray device, filter bag and bag cage, large particle sedimentation barrier diversion device, inlet and outlet, heating system, anti-blocking system, insulation system, electrical control system etc.

The upper case includes tubesheet, filter bag, bag cage, blowing device, clean air chamber etc.

The middle case includes a dusty flue gas inlet duct and a shell. The filter bag is hung in the middle case space.

Ash hopper is used to collect dust from the filter bag.

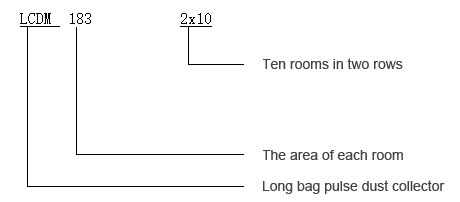

Model description

Range of Gas flow processing

10000~2000000m3/h, the outlet emission concentration is lower than 50-5-5mg/Nm3.

Applicable industry

Metallurgy, building materials, electricity, light industry, chemical industry, solid waste and other industries.

Main innovations:

● Modular upper box structure

● Fixed pipe blowing technology

● Safe operation and technical measures of bag dust collector

● Equal air supply technology for each compartment

● Optimized inlet and outlet air duct design, conducive to uniform distribution of air flow;

● Inlet and outlet temperature display , ash cleaning and unloading instructions;

● Off-line compartment cleaning can overcoming the drawbacks of online dust removal and reattachment, to ensure the best cleaning strength and effect;

● Each chamber exhaust valve adopts lifting valve structure, simple and reliable structure, good sealing performance;

● Pneumatic ash discharge valve can be automatically or manually controlled, reduce the operating time of ash transport equipment, reduce energy consumption;

● Automatic ultra-high and low temperature alarm can be set, automatic control of high temperature cold air valve cooling and ultra-low temperature filter bag protection measures (safety valve);

● Easy maintenance and repair, repair and bag change can be carried out in separate rooms under the normal operation of the system fan and dust collector;

● PLC control system;

● Provide two options of centralized control and control nearby the machine;

● Adapt to a wide changes in the properties of dusty gases;

LCDM long bag pulse series bag dust collector technical parameters

|

Model number |

Air volume (m3/h) |

Total filtration area(m2) |

Number of dust removal chambers(pcs) |

Total number of filter bags (pcs) |

Filter bag size(mm×mm) |

Filter wind velocity(m/min) |

Dust removal port resistance(Pa) |

Inlet gas dust concentration(g/Nm3) |

Outlet gas dust concentration(mg/Nm3) |

Dust removal efficiency(%) |

Injection pressure(MPa) |

|

LCDM183/6 |

59000 |

1098 |

6 |

450-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/7 |

69000 |

1281 |

7 |

525 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/8 |

79000 |

1465 |

8 |

600 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/9 |

89000 |

1648 |

9 |

675 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/10 |

99000 |

1830 |

10 |

750-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/11 |

109000 |

2013 |

11 |

825 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/12 |

119000 |

2196 |

12 |

900 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/13 |

129000 |

2379 |

13 |

975 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×7 |

139000 |

2562 |

14 |

1050-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×8 |

159000 |

2928 |

16 |

1200 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×9 |

179000 |

3295 |

18 |

1350-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×10 |

199000 |

3660 |

20 |

150-50 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×11 |

219000 |

4026 |

22 |

1650-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×12 |

239000 |

4392 |

24 |

1800 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×13 |

259000 |

4758 |

26 |

1950-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×14 |

279000 |

5125 |

28 |

2100 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

|

LCDM183/2×15 |

299000 |

5490 |

30 |

2250-5 |

130×6000 |

0.9 |

<1700 |

<100 |

<50-5 |

>99.9 |

≤0.35 |

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China