Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

DTII type stationary belt conveyor

Classification:

DTII stationary belt conveyor is a general purpose of products designed in a unified way. Its main parameters and performance are in line with ISO international standards. It is a conveyor system for conveying materials by single or multiple units.

Contact:

PRODUCTS

Details Introduction

Overview:

DTII stationary belt conveyor is a general purpose of products designed in a unified way. Its main parameters and performance are in line with ISO international standards. It is a conveyor system for conveying materials by single or multiple units.

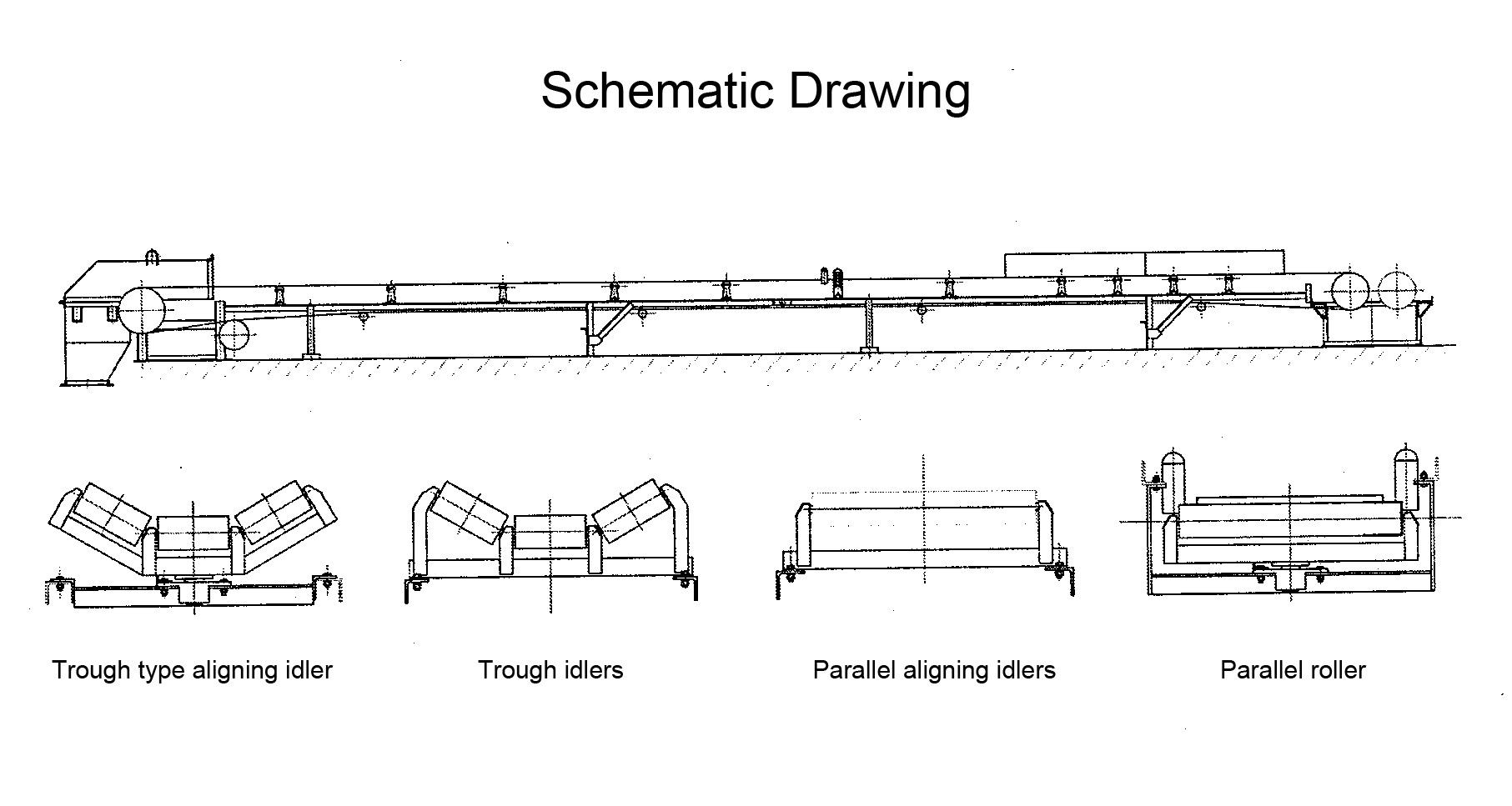

Major component

Head and tail wheel, frame, all kinds of rollers, rollers, tape, tension device, counterweight block, safety device, driving device, control device, etc.

Structural form

According to the conditions of use, it is classified into: horizontal transport, uphill transport, downhill transport, two-way transport, head drive, multi-point drive;

According to the structural characteristics, it is classified into: telescopic belt conveyor, fixed drop belt conveyor, rope frame hanging belt conveyor, steel cable traction belt conveyor, pipe frame quick contact fuselage belt conveyor, channel steel Angle iron fuselage belt conveyor, tubular belt conveyor;

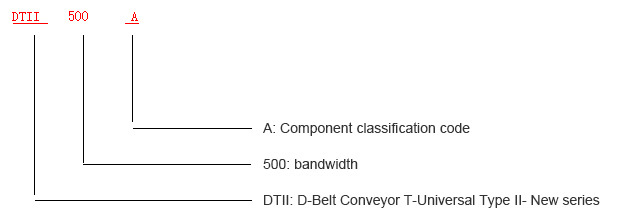

Model description

Application working condition

The accumulation proportion of the material that can be transported by the conveyor is within the range of 0.5-2.5/m3. Conveyor ambient temperature +40℃-25℃ range. For dustproof, heat resistance, cold resistance, waterproof, anti-corrosion, explosion-proof, flame retardant and other conditions, should take other measures.

The size of the material allowed to be transported by the conveyor depends on the bandwidth, belt speed, slot Angle and inclination, and also depends on the frequency of the occurrence of large materials. Maximum granularity applicable to various bandwidths. When conveying hard rock, after the bandwidth exceeds 1200mm, the particle size should generally be limited to the range of 350mm, and cannot be increased with the increase of bandwidth.

Application industry

It can be used in coal, chemical industry, building materials, metallurgy, electric power, light industry, grain, port, ship, thermal power and other industries to transport bulk or into a piece of goods.

Main innovations:

● Large throughput.

● Save equipment floor space.

● Completely solve the transmission Angle that cannot be reached by the ordinary pattern belt conveyor. Smooth transition from horizontal to inclined (or vertical);

● Low energy consumption, simple structure, easy maintenance.

● High strength tape, long service life.

● Low overall investment cost, can save 20%-30% of the investment cost

● Suitable for conveying easily scattered powder, granular, small block, paste and liquid materials;

Product specifications and main technical parameters:

Driving device selection:

This series of belt conveyor adopts Y series motor, hydraulic coupler, DBY or DCY type hard tooth surface conical cylindrical gear reducer; When the driving power is less than 55KW, the electric roller can be selected; According to the needs of users, we can choose other forms of drive devices for users.

|

Bandwidth B (mm) |

Tape velocity V(m/s) |

Maximum bulk |

|||||||||||

|

0.8 |

1.0 |

1.25 |

1.6 |

2.0 |

2.5 |

3.15 |

4 |

(4.5) |

5.0 |

(5.6) |

6.5 |

||

|

Transport capacity lv,m3/h |

|||||||||||||

|

500 |

69 |

87 |

108 |

139 |

174 |

217 |

-- |

-- |

-- |

-- |

-- |

-- |

100 |

|

650 |

127 |

159 |

198 |

254 |

318 |

397 |

-- |

-- |

-- |

-- |

-- |

-- |

150 |

|

800 |

198 |

248 |

310 |

397 |

496 |

620 |

781 |

-- |

-- |

-- |

-- |

-- |

200 |

|

1000 |

324 |

405 |

507 |

649 |

811 |

1014 |

1278 |

1622 |

-- |

-- |

-- |

-- |

300 |

|

1200 |

-- |

593 |

742 |

951 |

1188 |

1486 |

1872 |

2377 |

2674 |

2971 |

-- |

-- |

350 |

|

1400 |

-- |

825 |

1032 |

1321 |

1652 |

2065 |

2602 |

3304 |

3718 |

4130 |

-- |

-- |

350 |

|

1600 |

-- |

-- |

-- |

-- |

2186 |

2733 |

3444 |

4373 |

4920 |

5466 |

6122 |

-- |

350 |

|

1800 |

-- |

-- |

-- |

-- |

2795 |

3494 |

4403 |

5591 |

6291 |

6989 |

7829 |

9083 |

350 |

|

2000 |

-- |

-- |

-- |

-- |

3470 |

4338 |

5466 |

6941 |

7808 |

8676 |

9717 |

11277 |

350 |

|

2200 |

-- |

-- |

-- |

-- |

-- |

-- |

6843 |

8690 |

9776 |

10863 |

12166 |

14120 |

350 |

|

2400 |

-- |

-- |

-- |

-- |

-- |

-- |

8289 |

10526 |

11842 |

13158 |

14737 |

17104 |

350 |

Note: Conveying capacity is calculated based on horizontal transportation, dynamic stacking Angle of 20° and idler groove Angle of 35°

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China