Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

FU type chain conveyor

Classification:

FU chain conveyor is a new mechanical product for horizontal (or inclined ≤15°) conveying powder, granular materials and it is products that Innovative and improved design after introduction from overseas technology .

Contact:

PRODUCTS

Details Introduction

Overview

FU chain conveyor is a new mechanical product for horizontal (or inclined ≤15°) conveying powder, granular materials and it is products that Innovative and improved design after introduction from overseas technology . the superiority from its working principle, due to the material has internal friction and side pressure etc , The movement of the conveyor chain increases the internal pressure of the material in the groove and the internal friction between the particles. When the internal friction between the material layer is greater than the external friction between the material and the groove wall, the material flows forward with the conveyor chain like water. stable material flow can be formed when the ratio of material layer height and groove width meets certain conditions . Its performance is better than screw conveyor, buried scraper conveyor and other conveying equipment.

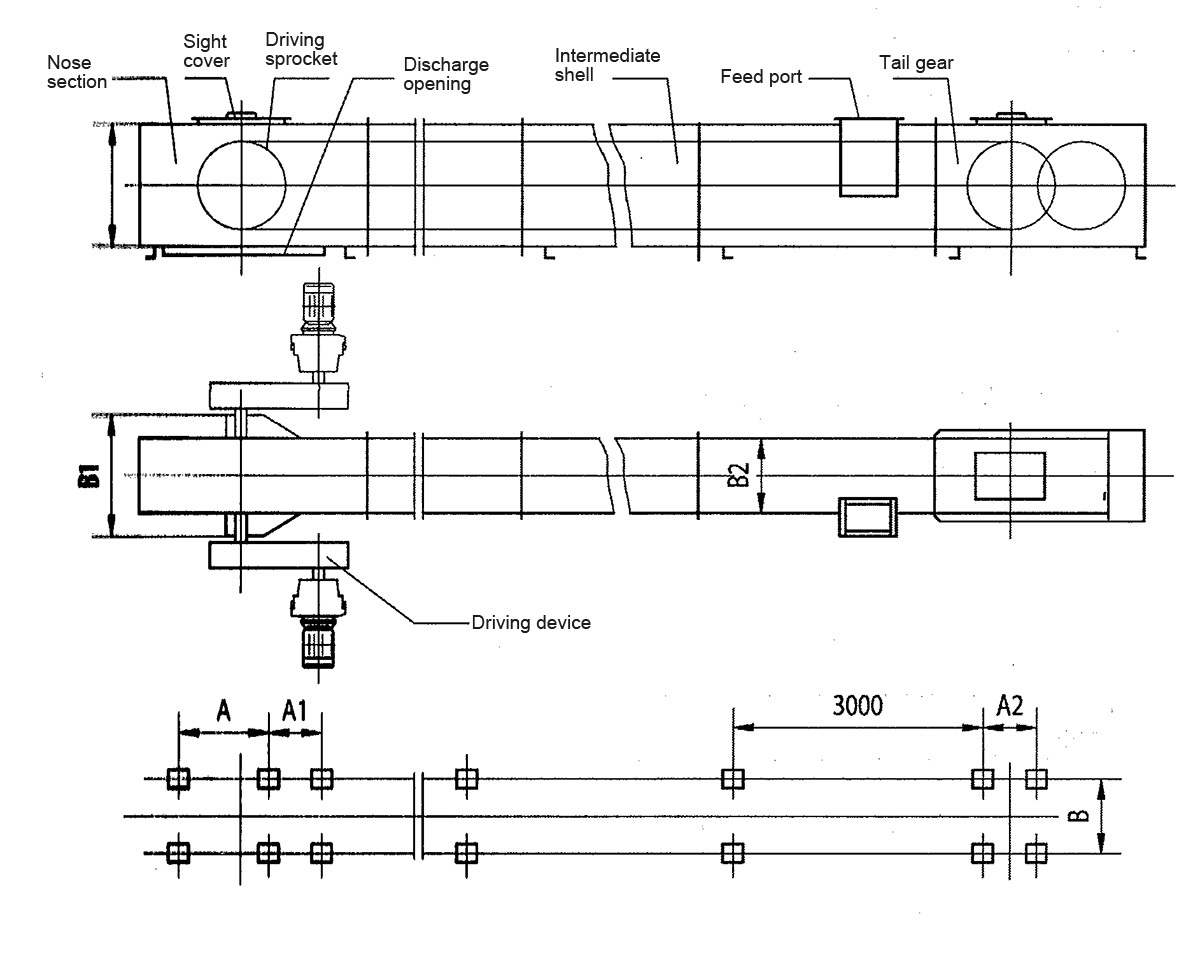

Main component

Head and tail wheel, medium indirect, chain, box, motor reducer, control device

Structural form

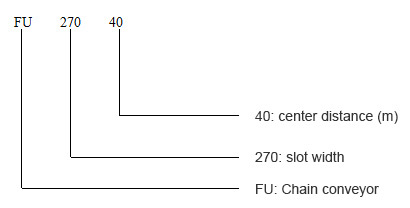

Model description

Application working condition

Suitable for continuous conveying of materials with climbing Angle (≤15°). The bulk density of the conveying material is 0.1 ~ 2.0 t/m3 and the working ambient temperature is within the range of -25℃ ~ +40℃.

Main innovations

● Low energy consumption, with the internal friction of the material, compared with the screw conveyor 40% ~ 60% power saving.

● Reasonable structure, novel design, advanced technology, complete series.

● Fully closed shell, good sealing performance, safe operation, reliable operation.

● Cost saving, power saving and durable, less maintenance, reduce consumption, improve efficiency.

● Large conveying capacity, allowing large quantities of materials to be transported in a small space, with a conveying capacity of 6 ~ 600m3/h.

● Flexible import and export, elevated, ground, pit, horizontal, climbing (≤15°) can be installed, conveying length can be designed according to the user.

● Long service life, transport chain with alloy steel processed by advanced heat treatment means, normal life > 5 years, roller life on the chain ≥2 ~ 3 years.

Application industry

Widely used in building materials, construction, chemical industry, mining, machinery, smelting, food processing and other industries, it is an ideal new conveying equipment.

Main technical parameters table:

|

Type number |

Slot width |

Ideal particle size |

10% Max size |

Maximum transmission slope |

Optimal throughput(m3/h) |

Material moisture |

||||||

|

Chain line velocity(m/min) |

||||||||||||

|

10 |

12 |

13.5 |

15 |

16 |

20 |

25 |

||||||

|

FU150 |

150 |

<4 |

<8 |

≤15° |

6-9 |

|

|

9-13 |

|

12-18 |

15-23 |

≤5% |

|

FU200 |

200 |

<5 |

<10 |

11-14 |

|

|

16-22 |

|

22-29 |

27-36 |

||

|

FU270 |

270 |

<7 |

<15 |

19-27 |

23-32 |

25-36 |

28-41 |

31-43 |

38-54 |

47-68 |

||

|

FU350 |

350 |

<9 |

<18 |

|

36-50 |

|

49-68 |

|

65-90 |

63-113 |

||

|

FU410 |

410 |

<11 |

<21 |

|

50-72 |

|

63-90 |

|

86-117 |

95-135 |

||

|

FU500 |

500 |

<13 |

<25 |

|

72-99 |

|

95-131 |

|

136-180 |

144-203 |

||

|

FU600 |

600 |

<15 |

<30 |

|

104-144 |

|

135-190 |

|

180-260 |

207-270 |

||

Note: The optimal conveying capacity is calculated based on cement as the material and the speed can be accelerated when transporting materials with small cut and temperature < 60℃ in other industries. the Material humidity ≤5% is wet hands form clumps, but throwing them away can disperse them

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China