Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Screw conveyor

Classification:

Screw conveyor is machine that uses rotating screw drived by motor and push the material to achieve the purpose of conveying. It can be horizontal, inclined or vertical transport,

Contact:

PRODUCTS

Details Introduction

Overview

Screw conveyor is machine that uses rotating screw drived by motor and push the material to achieve the purpose of conveying. It can be horizontal, inclined or vertical transport, the advantage is simple structure, small cross-sectional area, good sealing, easy operation and maintenance, easy to closely transport etc . it is divided into shaft or shaftless screw conveyor in conveying form and U-type or tube screw conveyor in appearance. The shaft type is for non-sticky dry powder materials , small particle materials and shaftless type is for material made of viscous and easily wound (such as: sludge, biomass, garbage etc) . The working principle is the material will pushed by the rotating screw blade and carry out transport, the force that prevents the material from rotating together with the blades of the screw conveyor is the weight of the material itself and the frictional resistance of the screw conveyor housing to the material. The spiral blade has solid surface type, belt surface type, blade surface type etc for choose according to the different of conveyor materials.

Main component

Screw conveyor is composed of screw machine body, inlet and outlet, driving device and control device. Consists of four parts.

The body of the screw machine is composed of head bearing, tail bearing, suspension bearing, screw, housing, cover plate and base. The driving device is composed of motor, reducer, coupling and base.

Structural form

The spiral blade has a direction on left or right rotation and the selection should be determined according to the layout of the conveyor.

There are three types of screw conveyors: horizontal fixed, inclined fixed and vertical . the first two are widely used and vertical conveying is seldom used due to specific feed is needed , conveying height restrictions.

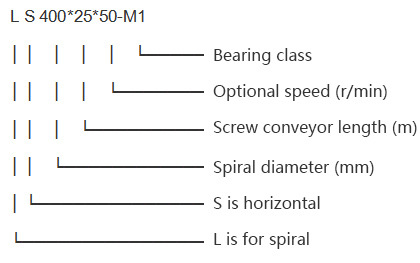

Model description

Application working condition

Suitable for horizontal or inclined (with an inclination angle not exceeding 20 °), it can control and continuously transport powdered and small block materials in a regular manner, with a working environment temperature range of -20~50 ℃,

Main innovations

● Simple structure, low cost

● Reliable work, easy maintenance and management.

● Compact size, small section size, small footprint. It is easy to enter and exit hatches and compartments during unloading and unloading operations in the port.

● sealed conveying for the material that easy to fly, hot and strong smell , can reduce environmental pollution, improve the working conditions of port workers.

● Easy to load and unload. The horizontal screw conveyor can be loaded and unloaded at any point on its conveying line; the configuration of a vertical spiral conveyor with a relatively spiral material retrieval device can have excellent material retrieval performance.

● reverse transport, make a conveyor to transport materials in two directions ( to the center or away from the center) at the same time.

● The material is easy to grind and wear during the conveying process, and the wear of spiral blades and chutes is also more serious.

Application industry

It can be used in conveying bulk on coal, chemical industry, building materials, metallurgy, electric power, light industry, grain, port, ship, thermal power and other industries .

Main technical parameters

|

Type LS |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

GX type |

|

|

200 |

250 |

300 |

400 |

500 |

|

|

|

|

|

Spiral diameter(mm) |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

Screw pitch(mm) |

100 |

160 |

200 |

250 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

|

Rotational velocity (r/min) |

140 |

120 |

90 |

90 |

75 |

75 |

60 |

60 |

45 |

35 |

30 |

|

Delivery capacity QΦ=0.33(m3/h) |

2.2 |

7.6 |

11 |

22 |

36.4 |

66.1 |

93.1 |

160 |

223 |

304 |

458 |

|

Power Pd 1=10m(KW) |

1.1 |

1.5 |

2.2 |

2.4 |

3.2 |

5.1 |

4.1 |

8.6 |

12 |

16 |

24.4 |

|

Power Pd 1=30m(KW) |

1.6 |

2.8 |

3.2 |

5.3 |

8.4 |

11 |

15.3 |

25.9 |

36 |

48 |

73.3 |

|

Rotational velocity (r/min) |

120 |

90 |

75 |

75 |

60 |

60 |

45 |

45 |

35 |

30 |

20 |

|

Delivery capacity QΦ=0.33(m3/h) |

1.9 |

5.7 |

18 |

18 |

29.1 |

52.9 |

69.8 |

125 |

174 |

261 |

305 |

|

Power Pd 1=10m(KW) |

1.0 |

1.3 |

2.1 |

2.1 |

2.9 |

4.1 |

4.7 |

6.8 |

9.4 |

14.1 |

16.5 |

|

Power Pd 1=30m(KW) |

1.5 |

2.3 |

4.5 |

4.5 |

7 |

8.9 |

11.6 |

20.4 |

28.3 |

42.2 |

49.5 |

|

Rotational velocity (r/min) |

90 |

75 |

60 |

60 |

45 |

45 |

35 |

35 |

30 |

20 |

16 |

|

Delivery capacity QΦ=0.33(m3/h) |

1.4 |

4.8 |

15 |

15 |

21.8 |

39.6 |

54.3 |

97 |

149 |

174 |

244 |

|

Power Pd 1=10m(KW) |

0.9 |

1.2 |

1.9 |

1.9 |

2.5 |

3.4 |

4.3 |

5.4 |

8.1 |

9.5 |

13.3 |

|

Power Pd 1=30m(KW) |

1.2 |

2.2 |

3.8 |

3.8 |

5.4 |

6.8 |

9.2 |

16 |

24.4 |

28.6 |

39.9 |

|

Rotational velocity(r/min) |

75 |

60 |

45 |

45 |

35 |

35 |

30 |

30 |

20 |

16 |

13 |

|

Delivery capacity QΦ=0.33(m3/h) |

1.2 |

3.8 |

11 |

11 |

17 |

31.7 |

46.5 |

73.0 |

99.3 |

139 |

199 |

|

Power Pd 1=10m(KW) |

0.75 |

1.1 |

1.6 |

1.6 |

2.1 |

3.1 |

3.7 |

4.6 |

5.7 |

7.7 |

11 |

|

Power Pd 1=30m(KW) |

1.1 |

1.8 |

3.4 |

3.4 |

4.4 |

5.6 |

8 |

14 |

16.7 |

23.2 |

33 |

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China