Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Wet desulfurization tower

Classification:

Wet desulphurization tower is equipment used to purify SO2 in flue gas, which is an ideal equipment to control air pollution.

Contact:

PRODUCTS

Details Introduction

Overview

Wet desulphurization tower is equipment used to purify SO2 in flue gas, which is an ideal equipment to control air pollution. The wet desulphurization tower is composed of the tower body, the stair platform outside the tower and the equipment inside and outside the tower. Its internal functions are divided into slurry circulation area of the tower tank, flue gas inlet in the middle of the tower, spray and fog removal area in the middle and upper part of the tower. Among them, the slurry circulation area includes a side-entry agitator or pulse suspension pipe network to prevent slurry settling, built in filtering net on tower and an oxidized air pipe network; The upper part of the flue gas inlet is provided with an air flow distribution device (optional); The spray layer in the upper part of the tower can be selected from 3 to 6 layers based on the desulfurization efficiency, the spacing of each layer is 1.8~2.0m, and each layer is equipped with a plurality of efficient desulfurization nozzles, with a coverage rate of more than 250%; According to the emission standards for fog droplet concentration, the mist eliminator can choose a variety of forms such as flat plate type, roof ridge type and tube bundle type. There are multiple circulating pumps outside the tower to connect the slurry circulation pool with the spray layer, and each circulating pump corresponds to a separate spray layer.

Working mechanism

Taking limestone as an example, the principle is as follows:

SO2 and SO3 in the flue gas will react as follows when they encounter water in the liquid drop:

SO2 + H2O → HSO3- + H+

SO3 + H2O → H2SO4

The resulting H2SO4 will be rapidly neutralized by limestone to maintain effective and durable absorption of SO2 and SO3.

Reacts with limestone

SO2 and SO3 react with fine limestone particles in the descending slurry droplets:

CaCO3 + 2H+ + HSO3- → Ca2+ + HSO3-+CO2↑+H2O

CaCO3 + H2SO4 → CaSO4 + CO2↑+H2O

The above is an ionic reaction, so the reaction takes place in solution, and the reaction with limestone is completed in the slurry tank of the absorber.

Oxidation reaction

Air blown into the slurry tank of the absorber oxidizes sulfites to sulfate:

Oxidation: 2Ca2++2HSO3-+O2→2CaSO4+2H+

The oxidation reaction is followed by gypsum crystallization:

Crystallization: CaSO4+2H2O→CaSO4·2H2O

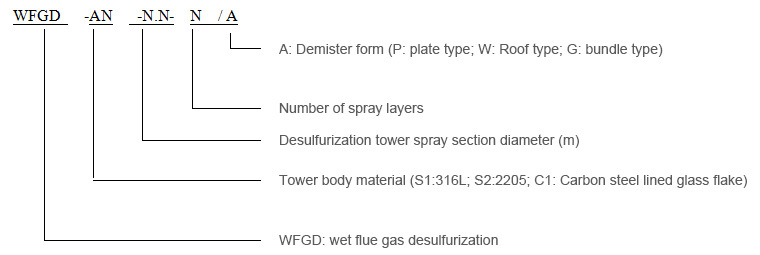

Model description (if there is no special description, A indicates the letter, N is number )

Treatment of Gas flow and concentration range

10000~3000000m3/h, SO2 inlet concentration ≤12000mg/Nm3, SO2 outlet emission concentration ≤35mg/Nm3.

Applicable industry

Power, chemical, light industry, metallurgy, building materials, and other industries boiler and kiln flue gas.

Characteristics of wet desulfurization tower

1, high desulfurization efficiency, up to 99.9%, especially suitable for flue gas purification with high SO2 content;

2, the source of desulfurization agent is wide, can use limestone, quicklime, slaking lime, magnesium oxide, papermaking white mud and other substances as desulfurization agent;

3, desulfurization agent utilization efficiency is high, calcium sulfur ratio is generally about 1.03;

4, desulfurization byproducts can be used as building materials;

5, the applicability of the unit is strong, the system utilization rate is greater than 95%.

Technical parameters of wet desulfurization tower (Part)

|

Model number |

Air volume (m3/h) |

Tower material |

Tower diameter(m) |

Agitator | Spray layer |

Nozzle (unit/layer) |

Mist eliminator form |

Resistance (Pa) |

Remark |

|

WFGD-S2-1.0-3/P |

8000- 12000 |

Alloy |

1.0 |

1 |

3 |

1 |

Flat plate type |

<1200 |

|

|

WFGD-S2-1.2-3/P |

12000- 17000 |

1.2 |

1 |

3 |

1 |

Flat plate type |

<1200 |

|

|

|

WFGD-S2-1.4-3/P |

17000- 24000 |

1.0 |

1 |

3 |

1 |

Flat plate type |

<1200 |

|

|

|

WFGD-S2-1.7-3/P |

24000- 35000 |

1.7 |

1 |

3 |

1 |

Flat plate type |

<1200 |

|

|

|

WFGD-S2-2.0-3/P |

35000- 50000 |

2.0 |

1 |

3 |

4 |

Flat plate type |

<1200 |

|

|

|

WFGD-S2-2.5-3/P |

50000- 75000 |

2.5 |

1 |

3 |

8 |

Flat plate type |

<1200 |

|

|

|

WFGD-C1-3.0-3/P |

75000- 100000 |

Carbon steel lined with glass scales |

3.0 |

2 |

3 |

8 |

Flat plate type |

<1200 |

|

|

WFGD- C1-3.5-3/P |

100000- 145000 |

3.5 |

2 |

3 |

12 |

Flat plate type |

<1200 |

|

|

|

WFGD- C1-4.2-3/P |

145000- 210000 |

4.2 |

2 |

3 |

16 |

Flat plate type |

<1200 |

|

|

|

WFGD- C1-5.0-3/W |

210000- 300000 |

5.0 |

3 |

3 |

24 |

Roof type |

<1200 |

|

|

|

WFGD- C1-6.0-3/ W |

300000- 420000 |

6.0 |

3 |

3 |

36 |

Roof type |

<1500 |

Air distribution board | |

|

WFGD- C1-7.0-3/ W |

420000- 580000 |

7.0 |

3 |

3 |

48 |

Roof type |

<1500 |

||

|

WFGD- C1-8.3-3/ W |

580000- 780000 |

8.3 |

4 |

3 |

64 |

Roof type |

<1500 |

||

|

WFGD- C1-9.7-3/ W |

780000- 1060000 |

9.7 |

4 |

3 |

92 |

Roof type |

<1500 |

||

|

WFGD- C1-11.2-3/ W |

1060000- 1400000 |

11.2 |

5 |

3 |

136 |

Roof type |

<1500 |

||

|

WFGD- C1-13.0-3/ W |

1400000- 1900000 |

13.0 |

5 |

3 |

136 |

Roof type |

<1500 |

||

|

WFGD- C1-15.0-3/ W |

1900000- 2500000 |

15.0 |

5 |

3 |

188 |

Roof type |

<1500 |

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China