Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

SDS desulfurization system

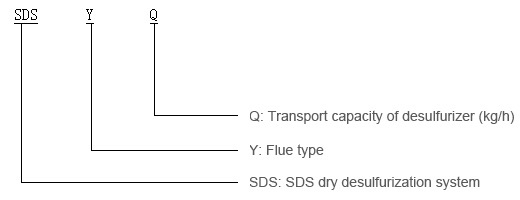

Classification:

The SDS desulfurization system is a complete set of desulfurization equipment used for dry flue gas desulfurization.

Contact:

PRODUCTS

Details Introduction

Summary

The SDS desulfurization system is a complete set of desulfurization equipment used for dry flue gas desulfurization, mainly used to remove acidic gases such as SO2, HCl, HF, etc. from flue gas. The SDS desulfurization system has high desulfurization efficiency, with a minimum emission concentration of SO2 below 15mg/Nm3, and is often used in ultra-low emission projects. The SDS desulfurization system has strong adaptability to changes in the concentration of SO2 in flue gas and fluctuations in flue gas load, and can stably maintain the desulfurization effect, thus it is widely used.

Desulfurization mechanism

Using baking soda (NaHCO3) as a desulfurizer, it is activated under the action of high-temperature flue gas to form a microporous structure, like popcorn exploding. The flue gas in the flue fully contacts with the activated desulfurizer to undergo a chemical reaction. SO2 and other acidic media in the flue gas are absorbed and purified by the desulfurizer, and the desulfurization by-products enter the bag filter with the airflow and are captured.

Main reactions:

2NaHCO3(S) = Na2CO3(s)+H2O(g)+CO2(g)

SO2(g)+Na2CO3(s) +1/2O2 = Na2SO4(s)+CO2(g)

Side effects:

SO3(g)+Na2CO3(s) = Na2SO4(s)+CO2(g)

Model description

Scope of application

Suitable for treating flue gas with SO2 concentration less than 500mg/m ³, ensuring that pollutant emissions meet the requirements of environmental emission standards.

Applicable industries

Suitable for industries such as power, steel, chemical, coke oven, glass kiln, etc.

Characteristics of SDS desulfurization system

1. The system is simple, the equipment is reliable and durable, the failure rate is low, and the service life is long.

2. The desulfurization efficiency can reach over 90%, and the utilization rate of desulfurizer is high.

3. The desulfurization system operates in a fully dry state, with no wastewater treatment or discharge issues, and no secondary pollution.

4. when the temperature of the desulfurization system drops by less than 10 ℃ and the exhaust temperature is high, it can be directly discharged from the original stack (without anti-corrosion).

5. The process flow is simple, the operation and maintenance are convenient, the adjustment is flexible, the controllability is good, and the degree of automation is high.

6. The amount of desulfurizer used is small, and the amount of by-products is low. The by-product Na2SO4 is a chemical product that can be recycled.

7. The equipment has a small footprint and flexible layout, especially suitable for situations where the site is limited.

Technical parameters

|

Model number |

Maximum conveying capacity of desulfurizer(kg/h) |

Delivery air volume (m3/h) |

Remark |

|

SDS-Y-160 |

160 |

800 |

|

|

SDS-Y-250 |

250 |

1600 |

|

|

SDS-Y-400 |

400 |

2700 |

|

|

SDS-Y-600 |

600 |

3500 |

|

|

SDS-Y-1000 |

1000 |

5500 |

|

|

SDS-Y-1500 |

1500 |

7800 |

|

|

SDS-Y-2200 |

2200 |

11000 |

|

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China