Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

MFS semi-dry desulfurization tower

Classification:

MFS semi-dry desulphurization tower is a common equipment for desulphurization which is shaped as tower structure and supported by steel frame. Air volume

Contact:

PRODUCTS

Details Introduction

Overview

MFS semi-dry desulphurization tower is a common equipment for desulphurization which is shaped as tower structure and supported by steel frame. From bottom to top, it is successively flue gas inlet, Venturi acceleration section and humidification reaction section. The hopper is at the lower part of the flue gas inlet which is convenient to discharge the block solid produced by the fluidized bed; The Venturi acceleration section is a hourglass shaped with two large ends and a small middle, and several parallel Venturi units can be arranged according to the size of the smoke volume. The humidification reaction section is in the shape of a straight cylinder, and the humidification spray gun is set at the lower part. All reactions are carried out in this area.

In the MFS semi-dry desulfurization tower, the desulfurizers that can be used are CaO, Ca(OH)2 and so on. The spray gun for humidification can be used in two forms according to the size of the tower and the choice of double fluid or high pressure reflux.

Working mechanism

The flue gas from the boiler is accelerated from the bottom of the desulfurization tower through the venturi tube and then rises into the humidification reaction section. Slaked lime is added at the upper end of venturi throat, and water is sprayed from the humidification reaction section to increase the humidity of flue gas and the moisture content of desulfurizer, forming a split-second gas-liquid-solid three-phase reaction state. The desulfurizer reacts with SO2 in the flue gas to produce calcium sulfite, which is collected in the rear electrostatic precipitator or bag precipitator, and then sent to the ash storage by pneumatic conveying or returned to the desulfurization tower for recycling through the return chute.

Chemical principle

Ca(OH)2+SO2→CaSO3+H2O

Ca(OH)2+2HCl→CaCl2+2H2O

Ca(OH)2+2HF→CaF2+2H2O

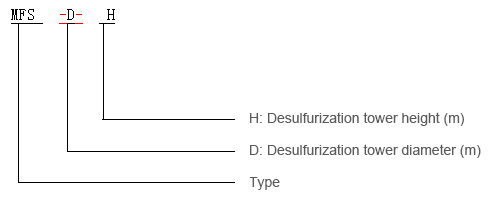

Main components & model description

Gas flow and concentration range

150000~700000m3/h, SO2 inlet concentration ≤1000mg/Nm3, SO2 outlet emission concentration ≤35mg/Nm3.

Applicable industry

power plants, steel mills on industries such as Metallurgy, building materials, electric power, light industry, chemical industry, solid waste etc

Characteristics of MFS semi-dry desulfurization

1. form a water film on the surface of dust particles by water-bearing recycled ash . pellicular water on the surface of the dust particles evaporates in the smoke stream instantaneously, forming an right reaction environment suitable for temperature and humidity in a very short time, and overcoming the wall sticking problem that may occur in the traditional semi-dry desulfurization reactor.

2. Due to the reduction of the time to establish the right reaction environment, it is possible to greatly reduce the total reaction time, which can effectively reduce the height of the desulfurization reactor;

3. The flue gas flows at high speed in the reactor, and the whole device has compact structure, small volume and reliable operation. The load adaptability of the device is good;

4. Desulphurization byproducts are dry, and no waste water is generated in the system. The final product has good fluidity and is suitable for pneumatic conveying. After desulfurization, the flue gas can be directly discharged without reheating, and the white smoke and rain can be eradicated.

By reducing the size and footprint of the absorber and avoiding the use of complex and expensive digestion and preparation systems, the initial investment and operating costs are greatly reduced;

6. High desulfurization efficiency, desulfurization efficiency can reach more than 90%, suitable for low sulfur content conditions.

technical parameters

|

Model number |

Air volume (m3/h) |

Desulfurization tower diameter (m) |

Flue gas flow rate (m/s) |

Desulfurization tower height(m) |

Desulfurization tower resistance(Pa) |

|

MFS-3600-27 |

150000-210000 |

Φ3.6 |

4~6 |

27 |

<1000 |

|

MFS-4200-28 |

210000-280000 |

Φ4.2 |

4~6 |

28 |

<1000 |

|

MFS-4800-29 |

280000-370000 |

Φ4.8 |

4~6 |

29 |

<1000 |

|

MFS-5400-30 |

370000-470000 |

Φ5.4 |

4~6 |

30 |

<1000 |

|

MFS-6000-32 |

470000-570000 |

Φ6 |

4~6 |

32 |

<1000 |

|

MFS-6600-32 |

570000-700000 |

Φ6.6 |

4~6 |

34 |

<1000 |

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China