Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

SYC Single machine dust collector

Classification:

SYC type pulse single machine dust collector is a small bag dust collector designed by our company after digestion and absorption of similar domestic products.

Contact:

PRODUCTS

Details Introduction

Overview

SYC pulse single machine dust collector is a small bag dust collector designed by our company after digestion and absorption of similar domestic products.

Working mechanism

The dusty gas enters the filtering chamber through the hopper (or lower open flange), and the coarser particles directly fall into the hopper or bin. The dusty gas is filtered by the filter bag, and the dust is trapped on the bag surface. The clean gas passes through the bag mouth to the clean gas chamber and is discharged into the atmosphere by the fan. When the dust on the surface of the filter bag continues to increase, causing the equipment resistance to rise to the set value, the time circuit breaker (or micro differential pressure controller) outputs a signal, and the programmable controller starts to work. The pulse valves are opened one by one, allowing compressed air to blow and clean the filter bag through the nozzle, causing the filter bag to suddenly expand. Under the action of reverse airflow, the dust attached to the bag surface quickly separates from the filter bag and falls into the hopper (or ash bin), and the dust is discharged through the flap valve. Spray blowing only cleans the filter bags one by one, while other filter bags continue to filter normally without stopping the fan.

Main component

This series of dust collector has six specifications, each specification can be divided into standard with ash bucket type A and open flange (no ash bucket) type B . Its structure is mainly composed of filter chamber, filter bag, clean air chamber, hopper, flap valve, pulse blowing ash cleaning device, electric control box etc. All the boxes adopt welding structure and access door is sealed with foam rubber strip.

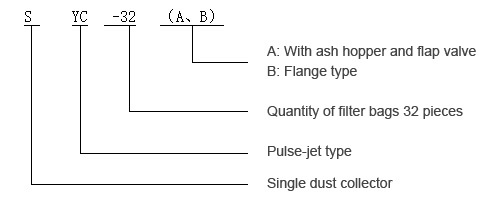

Model description

Technical innovation points:

● The cleaning method of pulse cleaning has good effect;

● High purification efficiency;

● Small footprint, simple installation,

● Long filter bag life,

● automation, simple operation

● Small maintenance workload

Range of Gas flow processing

1500-9000 m3/h

Applicable industry

non-fiber industrial dust removal purification and material recovery on Metallurgy, building materials, machinery, chemical, mining and other industrial enterprises

Technical performance

|

Performance/Model |

SYC-32 |

SYC-48 |

SYC-64 |

SYC-80 |

SYC-96 |

SYC-112 |

|||||

|

gas flow (m3/h) |

1500-2100 |

2100-3200 |

2900-4300 |

4000-6000 |

5200-7000 |

6000-9000 |

|||||

|

Total filtration area(m2) |

24 |

36 |

48 |

60 |

72 |

84 |

|||||

|

Filter wind velocity(m/min) |

1.00-1.50 |

1.00-1.50 |

1.00-1.50 |

1.10-1.70 |

1.20-1.70 |

1.20-1.80 |

|||||

| Number of filter bags (pieces) |

32 |

48 |

64 |

80 |

96 |

112 |

|||||

|

Inlet gas temperature(℃) |

≤120℃ |

||||||||||

|

Equipment Resistance (Pa) |

≤1200 |

||||||||||

|

Inlet dust concentration(g/m3) |

<200 |

||||||||||

|

Outlet emission concentration(mg/m3) |

≤50 |

||||||||||

| Dust removal with compressed air |

Pressure(Mpa) |

0.5-0.7 |

|||||||||

|

Air consumption(m3/min) |

0.10 |

0.14 |

0.20 |

0.24 |

0.29 |

0.34 |

|||||

|

Negative pressure (pa) |

5000 |

||||||||||

| Number of pulse valves (pcs) |

4 |

6 |

8 |

10 |

12 |

14 |

|||||

|

Fan motor power(KW) |

1.5 |

3.0 |

3.0 |

5.5 |

5.5 |

7.5 |

|||||

|

Weight(Kg) |

Type A (with ash hopper) |

1350 |

1620 |

1850 |

2360 |

2800 |

3200 |

||||

| Type B (without hopper) |

1220 |

1470 |

1670 |

2150 |

2540 |

2880 |

|||||

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China