Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

CMC series Warehouse top dust collector

Classification:

The CMC bin top dust collector is a device that separates the gas and ash using the principle of cloth bag filtration, removes the exhaust gas outwards, and maintains atmospheric pressure in the container. It is suitable for the top of various powder storage, especially for the top of the receiving bin in the pneumatic conveying process.

Contact:

PRODUCTS

Details Introduction

Overview

The CMC warehouse top dust collector is a device that uses the principle of bag filtration to separate gas and ash, remove exhaust gas outward, and maintain normal pressure inside the container. It is suitable for placement at the top of various powder storage warehouses, especially for the top of the receiving bin in pneumatic conveying processes.

Working mechanism

When the CMC series pulse bag filter is in operation, the dusty gas enters the dust collector through the exhaust hole at the top of the ash silo. Coarse dust particles directly fall into the ash silo, while fine dust particles enter the middle case body with the gas flow. The dust accumulates on the outer surface of the filter bag, and the filtered gas enters the upper case body through the bag mouth and the exhaust duct to the exhaust outlet of the outlet fan.

Main component

The dust collector is composed of upper case, middle case, spray device, filter bag and bag cage, pulse control system etc.

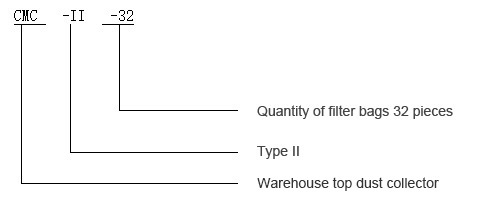

Model description

Range of Gas flow processing

500~10000m3/h, the outlet emission concentration is lower than 30-5mg/Nm3.

Applicable industry

The application of dust and fly ash storage in industries such as metallurgy, building materials, electricity, light industry, chemical industry and solid waste.

Technical innovation points:

● Single-machine modular structure

● Fixed pipe blowing technology

● Inlet and outlet temperature display , ash cleaning and unloading instructions;

● Easy maintenance and repair, repair and bag change can be carried out in separate rooms under the normal operation of the system fan and dust collector;

● Pulse controller system;

● Adapt to a wide range of changes in the properties of dusty gases;

Technical performance

The main technical parameters of CMC-Ⅱ pulse bag bin top dust collector are shown in Table 1

|

Model |

CMC-24 |

CMC-36 |

CMC-48 |

CMC-60 |

CMC -72 |

CMC-84 |

CMC-96 |

CMC-120 |

|

Filter area (m2) |

18 |

27 |

36 |

45 |

54 |

63 |

72 |

90 |

| Filter bag quantity |

24 |

36 |

48 |

60 |

72 |

84 |

96 |

120 |

| Filter bag specification |

Φ120 × 2000mm |

|||||||

|

Operating temperature ( ℃ ) |

<120 0 (terylene) |

|||||||

|

Equipment Pressure ( Pa ) |

1200~1500 |

|||||||

|

Inlet dust concentration |

<15(g/m 3 ) |

|||||||

|

Filter air efficiency (m/min) |

0.8~2.0 |

|||||||

|

Purification efficiency ( % ) |

99.5~99.9 |

|||||||

|

Handling gas flow m3 /h |

864~2160 |

1300~3250 |

1728~4320 |

2160~5400 |

2580~6450 |

3020~7550 |

3460~8650 |

4320~1800 |

|

Pulse solenoid valve(pcs) |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

|

Pulse width ( S ) |

0.1 ~0.2 (adjustable) |

|||||||

|

Pulse period ( S ) |

60 ~120 (adjustable) |

|||||||

|

Ash cleaning gas source pressure ( MPa ) |

0.4 ~0.6 |

|||||||

|

Air consumption ( m3/min ) |

0.1 ~0.3 |

0.1 ~0.5 |

0.2 ~0.7 |

0.2 ~0.8 |

0.25 ~1 |

0.3 ~1.2 |

0.3 ~1.3 |

0.4 ~1.7 |

|

Added fan power ( KW ) |

1.5 |

2.2 |

3.0 |

5.5 |

5.5 |

7.5 |

7.5 |

11.0 |

|

Total equipment weight ( kg ) |

980 |

1470 |

1960 |

2450 |

2940 |

3430 |

3800 |

4900 |

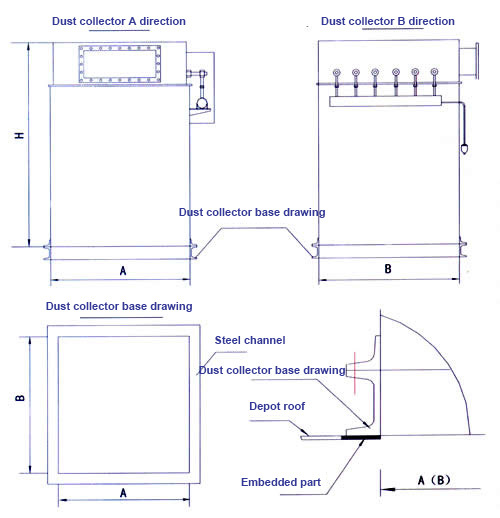

Outline dimension table (unit:mm)

The main technical parameters of CMC-Ⅱ pulse bag bin top dust collector are shown in Table 2

| Designation |

CMC-24 |

CMC-36 |

CMC-48 |

CMC-60 |

CMC-72 |

CMC-84 |

CMC-96 |

CMC-120 |

|

A |

1370 |

1370 |

1370 |

1370 |

1370 |

1510 |

1370 |

1510 |

|

B |

920 |

1320 |

1720 |

2120 |

2430 |

2430 |

3190 |

3430 |

|

H |

2650 |

|||||||

| Model of foundation channel steel |

[10 |

[14 |

||||||

Outline dimension table diagram

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China