Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Cartridge dust collector

Classification:

A cartridge dust collector is composed of a filter cartridge as the filtering element or a dust collector using pulse blowing. The cartridge dust collector can be divided into inclined insertion type, side installation type, lifting type and upper installation type according to the installation method. cartridge dust collectors can be divided into long fiber polyester filter cartridge dust collectors, composite fiber filter cartridge dust collectors, anti-static filter cartridge dust collectors, flame-retardant filter cartridge dust collectors, membrane filter cartridge dust collectors, nano filter cartridge dust collectors etc according to the filter cartridge material.

Contact:

PRODUCTS

Details Introduction

Overview

A cartridge dust collector is composed of a filter cartridge as the filtering element or a dust collector using pulse blowing. The cartridge dust collector can be divided into inclined insertion type, side installation type, lifting type and upper installation type according to the installation method. cartridge dust collectors can be divided into long fiber polyester filter cartridge dust collectors, composite fiber filter cartridge dust collectors, anti-static filter cartridge dust collectors, flame-retardant filter cartridge dust collectors, membrane filter cartridge dust collectors, nano filter cartridge dust collectors etc according to the filter cartridge material.

Working mechanism

After the dusty gas enters the hopper, due to the sudden expansion of the airflow cross-section and the effect of the airflow distribution plate, some coarse particles in the airflow settle in the hopper under the action of dynamic and inertial forces; Fine grained and low-density dust particles enter the dust filter chamber, and through a combination of Brownian diffusion and sieving effects, the dust settles on the surface of the filter material. The purified gas enters the clean air chamber and is discharged through the exhaust pipe and fan .

The resistance of the filter cartridge dust collector increases with the increase of the thickness of the dust layer on the surface of the filter material. Clean the dust when the resistance reaches a certain specified value. At this time, the PLC program controls the opening and closing of the pulse valve. Firstly, the lifting valve of the first chamber is closed to cut off the filtered airflow. Then, the electromagnetic pulse valve is opened, and the compressed air rapidly expands in the upper box for a short period of time, flowing into the filter cartridge, causing the filter cartridge to expand ,deform and generating vibration. Under the action of reverse airflow flushing, the dust attached to the outer surface of the filter bag is peeled off and falls into the hopper. After the dust cleaning is completed, the electromagnetic pulse valve closes, the lift valve opens, and the chamber returns to the filtering state. The cleaning process is carried out sequentially in each room, starting from the cleaning of the first room and ending with the next cleaning cycle. The fallen dust falls into the hopper and is discharged through the ash removal valve.

Product characteristics

1. The filter cartridge uses imported polyester fibers as the filter material, adhering a layer of sub micron ultra-thin fibers to the general filter material. The arrangement of fibers on this adhesion layer is very tight, and the extremely small sieve holes can block most of the sub micron dust particles on the surface of the filter material;

2. The use of pleated filter media can increase the filtration area and make the structure of the dust collector more compact;

3. The height of the filter cartridge is small, and the installation and maintenance workload is small;

4. Compared with dust collectors of the same volume, the filtration area is relatively large, the filtration wind velocity is small and the resistance is not high;

Range of Gas flow processing

500~1000000m3/h, the outlet emission concentration is less than 30-5mg/Nm3.

Applicable industry

Cartridge dust collectors are widely used in various industrial fields, including but not limited to the following: coal-fired power plants, steel smelting, cement industry, metallurgical industry, chemical industry, pharmaceutical industry, wood industry, powder recycling, grain processing etc

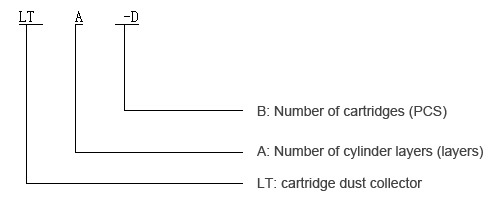

Model description

Technical performance

|

Model number |

Number of layers (layers) |

Number of cartridges (pcs) |

Total dust collection area (m2) |

Number of solenoid valves (pcs) |

Equipment weight (kg) |

|

LT-2-4 |

2 |

4 |

70 |

4 |

500 |

|

LT-2-16 |

2 |

16 |

280 |

8 |

1400 |

|

LT-2-36 |

2 |

36 |

630 |

18 |

2900 |

|

LT-3-6 |

3 |

6 |

105 |

6 |

650 |

|

LT-3-12 |

3 |

12 |

210 |

6 |

900 |

|

LT-3-24 |

3 |

24 |

420 |

6 |

1500 |

|

LT-4-16 |

4 |

16 |

280 |

8 |

1100 |

|

LT-4-64 |

4 |

64 |

1120 |

32 |

4000 |

|

LT-4-80 |

4 |

80 |

1400 |

40 |

5000 |

RELATED PRODUCTS

RELATED CASE

Qualifications

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China