Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Double alkali (sodium calcium) desulfurization technology

SubmitDouble alkali (sodium calcium) desulfurization technology

Chemical principle

1. Absorb

NaOH+SO2 → NaHSO3

Na2SO3+SO2+H2O → 2NaHSO3

The absorption solution containing sodium bisulfite is neutralized by liquid alkali to obtain sodium sulfite:

NaOH+NaHSO3 → Na2HSO3+H2O

2. Replacement of regeneration

the following reaction occurs When the absorption solution containing sodium sulfite meets and mixes with lime water, :

Ca(OH)2+Na2SO3→CaSO3↓+2NaOH

That is calcium sulfite precipitates, and sodium hydroxide is replaced again into the absorption tower to absorb sulfur dioxide.

3. Oxidation

the following reactions occur when dealing with flue gas containing oxygen or sulfur trioxide :

NaHSO3+O2→Na2SO4 +H2O

Na2SO3+O2→Na2SO4

NaOH+SO3→NaHSO4

Na2SO4+SO3+H2O→2NaHSO4

NaOH+NaHSO4→Na2SO4+H2O

Ca(OH)2+Na2SO4→CaSO4↓+2NaOH

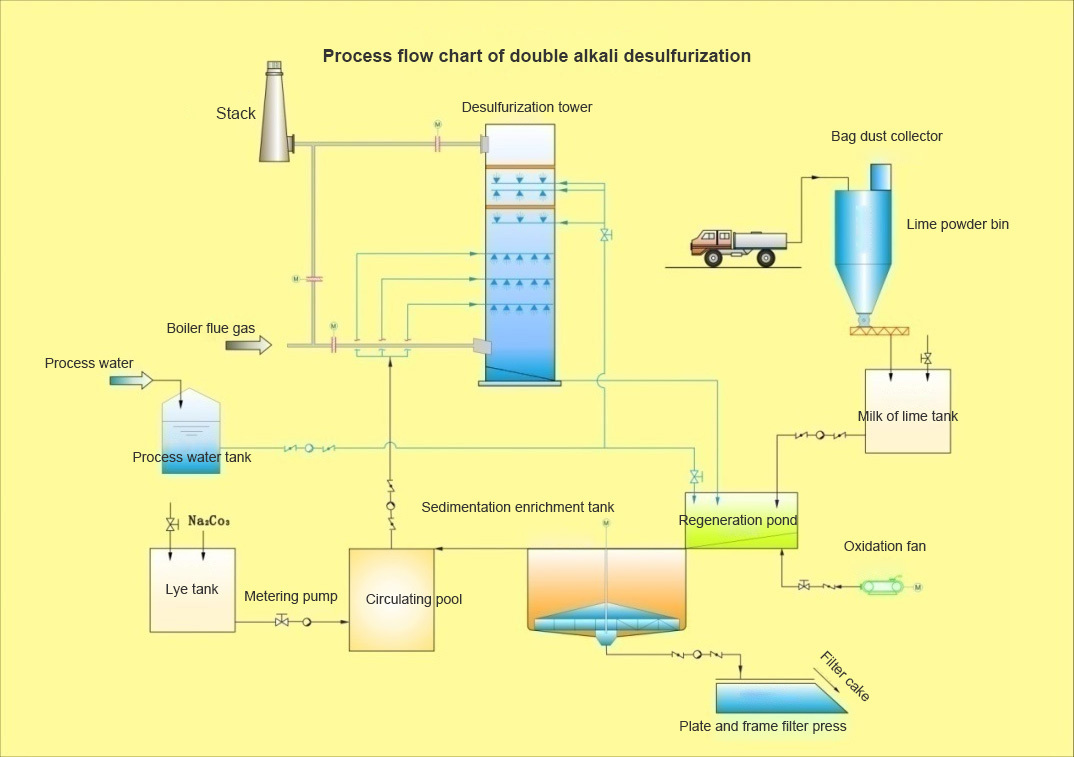

Process flow diagram

Process principle introduction

Na2CO3 or NaOH solution as the first absorption solution and then limestone or lime solution used as the second alkaline solution for regeneration. the solution continues to be recycled after regeneration,. The SO2 obtained by this method still precipitates in the form of CaSO3 or CaSO4. the scaling and blockage are avoided due to the production process of its product is outside of the absorption tower .

The main function of equipment and process systems

1. Flue gas systems: flue pipeline , diverter damper and sealing devices etc .

2. Absorption System: reverse flow spray absorption tower to complete the absorption of SO2 and SO3.

3. The slurry preparation system: lime powder storehouse, gasification equipment,Dust removal device, metering and conveying device, lime milk tank, dosing pump etc ;

4. Circulating system: regeneration tank, sedimentation and concentration tank, circulating tank, oxidation system, various circulating pipelines and pumps etc ;

5. Control system: electrical control and thermal instrumentation etc.

Technical characteristics

1. Double alkali desulfurization system can be combined with dust removal , using an integrated dust removal and desulfurization device to simultaneously perform desulfurization and dust removal

2. Sodium alkali absorbent has High reactivity, fast absorption rate, and the liquid to gas ratio can reduce , and thus reducing operating costs can also decrease investments in water tanks, pumps, and pipelines.

3. there is no existed of fouling in the tower and slurry plugging problems since external circulation of the tower .

4. Sodium alkali recycling with minimal loss

5. Lime as regenerant (actual consumption of material), safe and reliable, widely sources, low price

6. Easy to operate, the system can be long-term stable operation

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China