Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Limestone (lime) - gypsum desulfurization technology

SubmitLimestone (lime) - gypsum desulfurization technology

Chemical principle

1. the following reactions occur when SO2 and SO3 in flue gas encounter water in droplets :

SO2+H2O→HSO3-+H+

SO3+H2O→H2SO4

The generated H2SO4 will be quickly neutralized by limestone to maintain the effective and persistent absorption of SO2 and SO3 .

Reacting with limestone

SO2 , SO3 react with small limestone particles in descending slurry droplets :

CaCO3+2H++HSO3-→Ca2++HSO3-+CO2↑+H2O

CaCO3+H2SO4→CaSO4+CO2↑+H2O

Above is an ion reaction and it occurs in solution , the reaction with limestone is completed in the absorption tower slurry pool.

Oxidation reaction

Air blown into the slurry pool of the absorption tower oxidizes sulfites to sulfates:

Oxidation: 2Ca2++2HSO3-+O2→2CaSO4+2H+

The oxidation reaction is followed by gypsum crystallization:

Crystals: CaSO4+2H2O→ CaSO4·2H2O

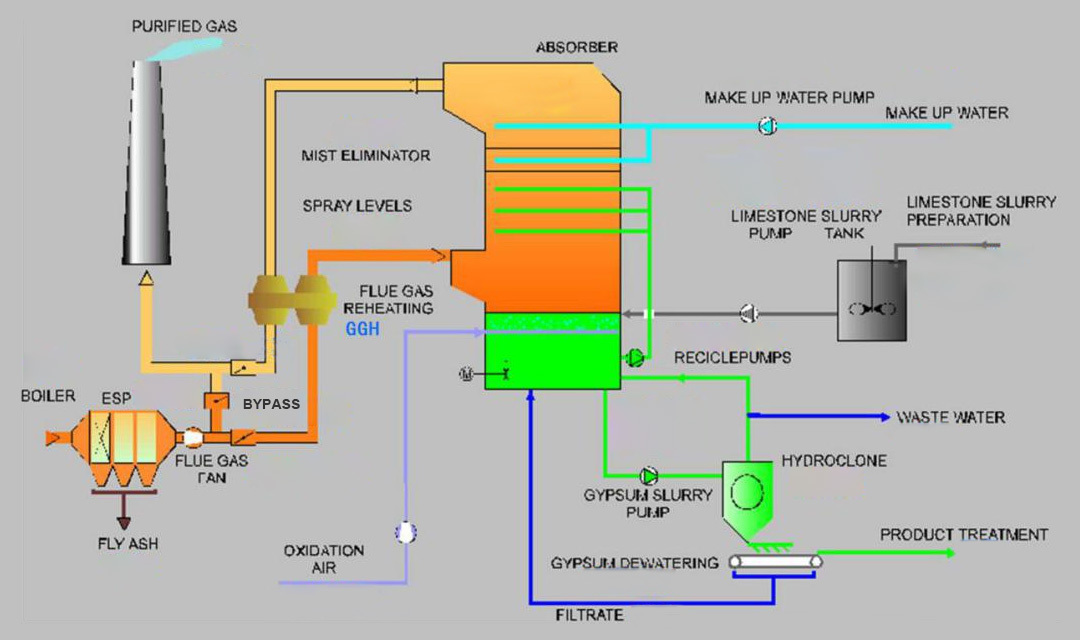

process flow diagram

Process principle Introduction

This process uses limestone as a desulfurization absorbent, which is crushed and ground into powder and mixed with water to make an absorption slurry. In the absorption tower, the absorption slurry is mixed with the flue gas, and the sulfur dioxide in the flue gas reacts chemically with the calcium carbonate in the slurry and the blown in oxidizing air to absorb and remove sulfur dioxide. The final product is gypsum, which is treated by the gypsum dehydration system. The filter cake product can be stored for comprehensive utilization, and the clear liquid is returned to the desulfurization circulation system. After desulfurization, the clean flue gas is treated with a defogger to remove fog droplets and finally discharged through the stack to meet the standard.

The main function of equipment and process systems

1. The flue gas systems: flue pipe , gas baffle, seal fan and gas - gas heater (GGH) and other key equipment

2. Absorption System: absorber tower ,the system complete absorption of SO2, SO3 and other harmful gases in the tower

3. The slurry preparation system: mill (wet grinding when used), bunker (when dry pulping), tank, stirrer, slurry pump

4. Gypsum dewatering system: hydrocyclones and vacuum belt dehydrating machine and other key equipment

5. Emergency slurry tank : slurry tank, regional slurry tank and the discharge line

6. Thermal control system : Including complete thermal measurement, automatic adjustment, control, protection and thermal signal alarm device .

Technological Innovation

1. With a detachment efficiency of over 98%, it has strong adaptability to coal types and can be used for high, medium, and low sulfur coal types;

2. Desulfurization agent is come from a wide range of sources and inexpensive .

3. The utilization efficiency of desulfurization agent is high and calcium sulfur ratio is around 1.03.

4. The desulfurization product is gypsum (calcium sulfate dihydrate), which can be used as building materials and is also easy to handle;

5. The unit has strong applicability and the system utilization rate is greater than 95%.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China