Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Magnesium oxide desulfurization technology

SubmitMagnesium oxide desulfurization technology

Process principle introduction

Magnesium oxide desulfurization technology is a desulfurization process with a maturity second only to calcium method. It involves the reaction of magnesium's alkaline oxide with water to form hydroxide, which then undergoes acid-base neutralization reaction with sulfuric acid solution formed by dissolving sulfur dioxide in water. Magnesium oxide reacts to produce magnesium sulfite and magnesium sulfate, which are then oxidized to produce magnesium sulfate.

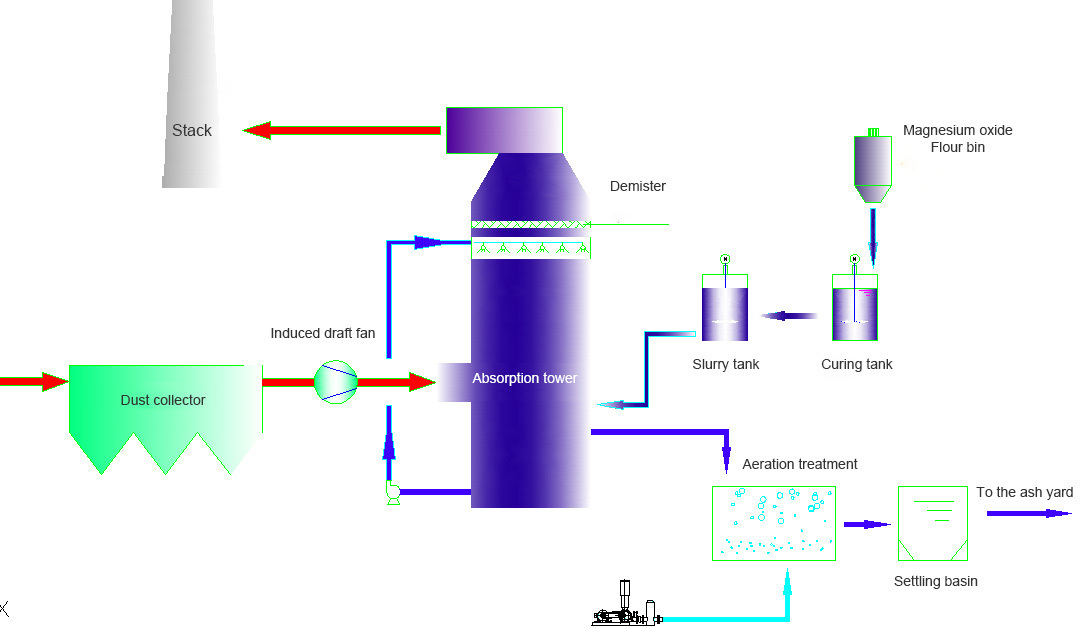

Process flow diagram

3. Principles of chemistry

(1) Preparation of magnesium oxide slurry

MgO(solid)+H2O→Mg(OH)2(slurry)

Mg(OH)2(slurry)→Mg2++2OH-

(2) Absorption of SO2

SO2 (gas) + H2O→ H2SO3

H2SO3→H++HSO3-

HSO3-→H++SO32-

Mg2++SO32-+9H2O→MgSO3•3H2O+MgSO3•6H2O

SO2+MgSO3•6H2O→Mg(HSO3)2+5H2O

Mg(OH)2+SO2→MgSO3+H2O

MgSO3+H2O+SO2→Mg(HSO3)2

(3) Oxidation of desulfurization products

MgSO3+1/2O2+7H2O→MgSO4•7H2O

The main functions of equipment and process system

1. Flue gas system: flue pipeline , flue gas baffle door and sealing device etc.

2. Absorption system: reverse flow spray absorption tower to complete the absorption of SO2 and SO3.

3. Slurry preparation system: magnesium oxide powder bin, gasification device, dust removal device, metering and conveying device, magnesium oxide slurry storage tank, dosing pump etc

4. Circulating system: regeneration tank, sedimentation concentration tank, circulating pool, oxidation system, circulating pipelines and pumps of various parts etc

5. Control system: electrical control and thermal instruments etc

Technical characteristics

1. Raw materials of magnesium oxide are easy to obtain - China has abundant magnesium oxide resources with reserves of about 16 billion tons, accounting for about 80% of the world ;

2. The circulating liquid is in the form of a solution, which is not easy to scale and will not be blocked;

3. High desulfurization efficiency;

4. Less Investment and low operating costs;

5. High operation reliability and strong adaptability to flue gas fluctuations;

6. The desulfurization product is easy to dispose of, and the amount of sludge under the same conditions is only 1/20 of the limestone-gypsum method.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China