Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

SDS dry desulphurization technology

SubmitSDS dry desulphurization technology

SDS dry desulphurization is Sodium-based dry desulphurization which uses powdered sodium bicarbonate (baking soda) as deacidifier to absorb and remove acidic gases such as SO2,HCl and HF of flue gas. This technology has become one of the main technologies for flue gas desulfurization due to high desulfurization efficiency, wide application range and no secondary pollution . it is widely used in coal power, chemical industry, metallurgy, cement and other industrial fields, especially for the treatment of low concentration SO2 waste gas.

Desulfurization mechanism

Baking soda (NaHCO3) as a desulphurization agent, the surface and internal formation of microporous structure active action by high temperature flue gas , like popcorn is popped and the specific surface area of powdered baking sodagreatly increasing . The acid substance (SO2 , HCl) of flue gas is fully contact with the activated desulfurizer and purified by chemical reaction, and the Na2SO4 by-product is collected by bag dust collector with the air flow .

Main reactions:

(1)2NaHCO3(S) = Na2CO3(s)+H2O(g)+CO2(g)

(2)SO2(g)+Na2CO3(s) +1/2O2 = Na2SO4(s)+CO2(g)

Side effects:

(3)SO3(g)+Na2CO3(s) = Na2SO4(s)+CO2(g)

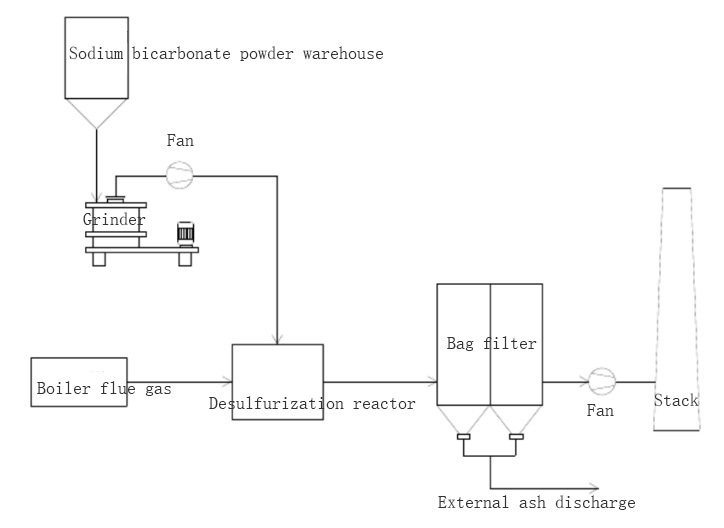

Process flow

The sodium bicarbonate powder is transported to the factory by car and to the silo by ton bag lifting. The sodium bicarbonate powder is successively transported to the desulfurization reactor (or flue) through the variable frequency controlled quantitative feeder, grinding system and conveying fan at the lower part of the bunker, and reacts with the flue gas at a high mass transfer rate to remove the acid gas of flue gas. The feeding equipment adopts frequency conversion control, and adjusts the amount of sodium bicarbonate powder online according to the emission concentration of SO2 to ensure that meets the emission standard.

System composition

Raw material silo, metering feed system, grinding machine, conveying and spraying system, desulfurization reactor, electric control system

Complete equipment of grinding machine

Technical characteristics

(1) Simple process system , reliable and durable equipment, low failure rate and long service life.

(2) The desulfurization efficiency can reach over 90% and the utilization rate of desulfurizer is high.

(3) Fully dry operation, no waste water treatment and discharge problems, no secondary pollution.

(4) The temperature of the desulfurization system decreases to only around 10 ℃ and the exhaust gas temperature is high which can be directly discharged from the original stack (without anti-corrosion).

(5) Simple process, easy operation and maintenance, flexible adjustment, good controllability and high degree of automation.

(6) The amount of desulfurizer and by-product is small. the Na2SO4 by-product is a chemical product and can be recycled.

(7) Small footprint and flexible layout , especially suitable for on-site venues with restrictions.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China