Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

SDA semi-dry desulphurization technology

SubmitSDA semi-dry desulphurization technology

SDA (Spray drying absorption) semi-dry desulphurization means rotating atomization drying absorption semi-dry desulphurization. Its using calcium hydroxide slurry as the deacidifier to absorb and remove acidic gases such as SO2 , HCl & HF of flue gas and has become one of the main technologies for desulfurization due to high desulfurization efficiency, wide application range and no secondary pollution after treatment. The technology is widely used in coal power, chemical industry, metallurgy, cement and other industrial fields, especially for the treatment of medium concentration SO2 waste gas.

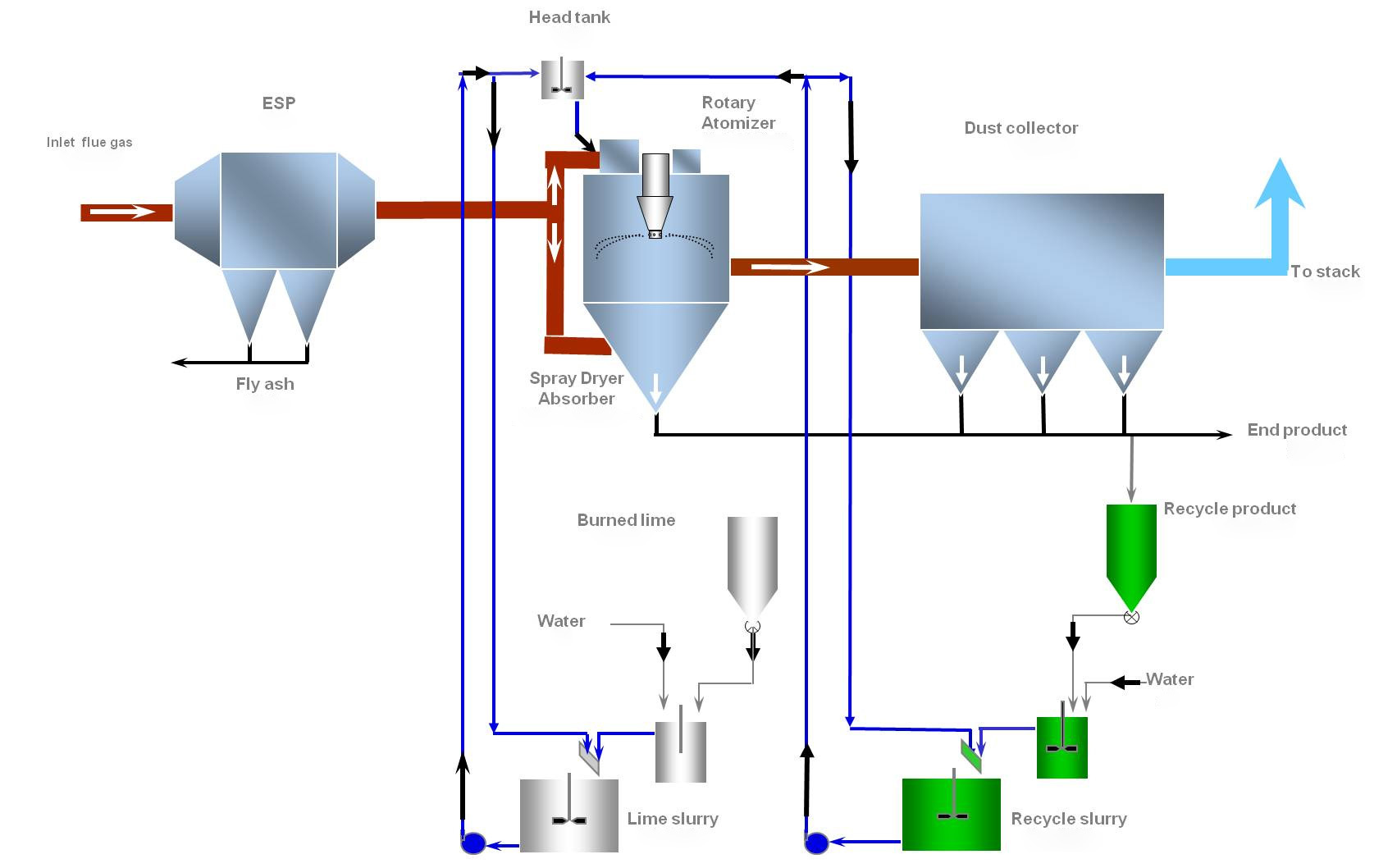

Desulfurization process and mechanism

The slaked lime powder is mixed with water to make a slurry, which is fed to the rotary atomizer through high tank or conveying pump. The slurry is atomized into 50 micron droplets by a rotating atomizer and SO2 is removed after the gas-liquid-solid three-phase reaction , the resulting product is hydrated calcium sulfate and it is quickly dried and dehydrated to form desulphurized ash by high temperature flue gas, the desulphurized ash is collected by the subsequent dust collector, and part of it is recycled to improve the utilization rate of the desulphurizer, and the other part is discharged.

Main reactions:

(1)2Ca(OH)2+SO2 = Ca2SO3+2H2O

(2)Ca(OH)2+2HCl = CaCl2+2H2O

(3)2CaSO3+O2= 2CaSO4

Process flow

System composition

Deacidification reactor, rotary atomization system, pulping system, water system, desulfurization ash collection system, electric control system

Technical characteristics

(1) It has a removal efficiency which close to that of wet desulfurization, up to 95%.

(2) Reactant waste water generation, no secondary pollution, follow-up equipment and flue pipeline, stack without anti-corrosion.

(3) Compared with CFB semi-dry desulfurization , it didn't have return system, dust concentration at the inlet of the dust collector is very low, equal to the concentration of particles in the original flue gas;

(4) Simple system, stable operation, low resistance, low operating cost;

(5) Multiple components of acid pollutants such as SO2, HCl and HF can be simultaneously remove.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China