Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

MFS Dry / semi-dry flue Gas Desulfurization technology

SubmitMFS Dry / semi-dry flue Gas Desulfurization technology

Process principles Introduction

The flue gas containing dust and SO2 coming out of the boiler rises through the Venturi tube from the bottom of the desulfurization tower and enters the tower. after being digested with water in the digester, quicklime (CaO) is stored in the lime silo. add a certain amount of quicklime and water at the upper end of the Venturi throat, mix and flow with the flue gas in the desulfurization tower, and react with SO2 in the flue gas to generate calcium sulfite, which enters the rear electrostatic precipitator or bag filter. after the reaction products and coal ash are collected by the dust collector, a portion of them are returned to the tower through an air chute for further circulation. the effect of hydrated lime is fully utilized, reducing its usage and improving desulfurization efficiency.

Chemical principle

Ca(OH)2+SO2→CaSO3•1/2H2O+1/2H2O

Ca(OH)2+SO3+H2O→CaSO4•2H2O

Ca(OH)2+HCl→CaCI2+2H2O

Reaction in Absorber tower:

Ca(OH)2+SO2→CaSO3+H2O

Ca(OH)2+SO3→CaSO4+H2O

Ca(OH)2+2HCl→CaCl2+2H2O

Ca(OH)2+2HF→CaF2+2H2O

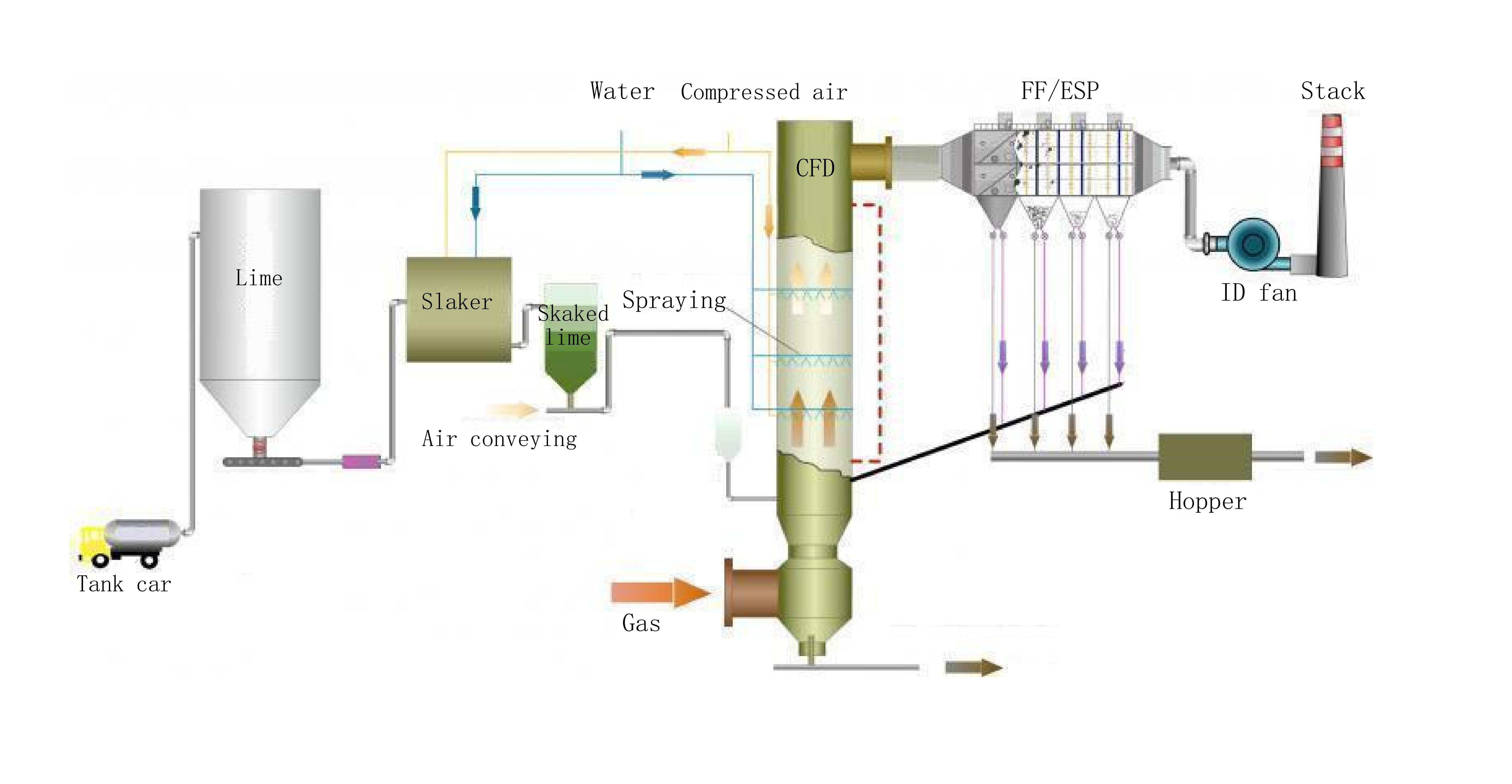

Process flow Diagram

System Composition

1. Flue pipeline system: flue pipeline, return air duct , flue damper and sealing devices etc.

2. Absorber system: the empty tower structure with a Venturi nozzle is used to absorb SO2 and SO3 by adding water to humidify and cool the flue gas and hydrated lime powder;

3. Dust collector system: excessive desulfurization products and hydrated lime powder mixture are discharged together with the flue gas and captured in the dust removal system;.

4. Desulfurization ash recycling system: a portion of the desulfurization reaction products are returned to the tower through an air chute for further circulation after being collected by the dust collector ;

5. Absorbent supply system : composed of lime powder silo and auxiliary conveying system;

6. Process water system: digests quicklime in the digester and cools , humidifies the flue gas through high-efficiency atomizing nozzles;

Technological Innovation

1. CFB technology uses quicklime (CaO) digestion and ash circular humidifier integrated design to ensure high-quality digest slaked lime (Ca(OH)2) put into circulation desulfurization reaction immediately .

2. water film will be form on the surfact of dust particles by use of recycled gray carry water . it will evaporates instantly in the flue gas flow, forming an ideal reaction environment with suitable temperature and humidity in a very short time, while also overcoming the wall sticking problem that may occur in traditional semi dry desulfurization reactors .

3. Due to the reduced time required to establish an ideal reaction environment, it is possible to significantly reduce the total reaction time, which can effectively lower the height of the desulfurization reactor .

4. The flue gas flows at high speed in the reactor, and the entire device has a compact structure, small volume, and reliable operation. Good load adaptability of the device.

5. The by-products of desulfurization are in a dry state and produces no water. The final product has good mobility and suitable for pneumatic conveying. after desulfurization, the flue gas can be directly discharged without further heating, white misty rain is eliminating.

6. Low requirements for absorbents, it is widely available.

7. reducing the size of the absorber and reduce footprint , avoid the use of complex and expensive preparation of the digestive system, which greatly reduces the initial investment and operating costs

8. The desulfurization efficiency is high, it can up to 90%.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China