Wuhan SY Blue Sky Environmental Technology Engineering Co., Ltd.

Long bag low pressure pulse Injection fabric filter technology

SubmitLong bag low pressure pulse Injection fabric filter technology

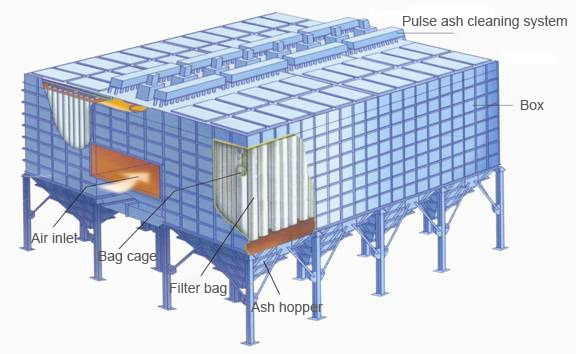

Long bag low pressure pulse Injection fabric filter is highly efficient equipment developed on the basis of conventional short bag pulse jet fabric filter and air box pulse jet fabric filter,It has the technical characteristics of large gas flow processing, good dust cleaning effect, high dust removal efficiency, reliable operation, convenient maintenance and small footprint .

This device has been widely used in steel, power, chemical, cement, metallurgy and other fields .

Equipment body, pulse jet system, gas distribution system, filtration system, hopper, exhaust system, electric control system

Technological Innovation

1. gas distribution technology : The core technology is gas distribution combined with our company design philosophy, A series of measures is use to avoid the filter bag from being washed away and evenly distribute the smoke to each bag, ensuring that the filter bag can withstand the load evenly and extend its service life while minimizing equipment resistance.

2. Air intake method and airflow distribution technology : Intake uniform distribution technology which developed by SY Blue Sky has the following characteristics: the inlet and outlet airflow channels with equal air supply can guide the airflow and flow towards the designated space, ensuring smooth and gentle airflow; Short process and low local resistance.

3. Upper case modular technology: to ensure that the spray pipe and bag holes of tubesheet can be strict alignment to ensure cleaning effective and protection filter bag. the upper case is processed and manufactured in the factory, it will assembled with a spray device and shipped as a whole after installation.

4. Fixed tube spray ash cleaning technology: (a) Spray tube on the mold positioning hole and making the nozzle; (b)Spray tube with tubesheet is positioned assembly in the factory and strict inspection is conducted to ensure the eccentric spacing is less than 1mm;(c) Check injection device one by one before deliver . (d) tubesheet and blowing device will be packed as a set during transportation and installation.

5.Low pressure pulse Injection technology: High pulse pressure Injection will bring adverse effect on the service life of filter bag, and dust layer adhere to the filter bag will be completely break up. not only is it not conducive to dust falling into the ash hopper by its own gravity, but it also easily causes secondary adsorption of dust

6. uniform air supply technology : the inlet and outlet airflow channels with uniform air supply are used to guide the airflow towards the designated space, ensuring a reasonable smoke intake and uniform smoke distribution for each individual dust collector; A baffle is installed inside the middle box to prevent direct flushing of the filter bag by the inlet airflow, allowing the flue gas to flow evenly through the bag. At the same time, it has a pre separation function for large particle dust.

Related Tech

Inquire

Leave a message and you will receive a surprise gift!

Head Office Address: No. 1178, Gaoke Building, Jiayuan Road, Hongshan District, Wuhan, Hubei, China

WhatsApp/Mobile: +86-13801339781

Factory Address: No. 283 Zhongshan Avenue, Jinshan Street Office, Huangshi Economic Development Zone, Hubei, China